Source: nelhydrogen.com

Share

Nel Hydrogen is a global hydrogen technology company that delivers optimal solutions to produce, store, and distribute hydrogen from renewable energy sources. Our manufacturing facilities are in Norway, Denmark, and the United States, and are supported by a world-wide sales and service network. We are publicly traded on the Oslo Stock Exchange (NEL.OSE). Nel Hydrogen is considered a “pure play” company for investors, meaning we solely focus on one line of business. In our case: hydrogen. We continuously strive to improve our product offering to maintain our earned leadership position and remain at the forefront of hydrogen technology development. Our vision is to empower generations with clean energy forever. That is a lofty goal; however, the momentum is building across public and private enterprises on a global scale to dramatically reduce our carbon footprint on the planet, and hydrogen is becoming a viable, clean alternative to fossil fuels in many impactful applications for industry, mobility, and energy.

Frontrunner in Hydrogen Electrolysers and Fueling Stations

We currently serve a range of diverse customers with leading hydrogen technologies. For example, Nel is the world’s largest hydrogen electrolyser manufacturer with more than 3,500 units delivered in 80+ countries since 1927. For readers new to the hydrogen topic, to put it simply, an electrolyser is a system the uses electricity to break water into hydrogen and oxygen in a process called electrolysis. Through electrolysis, the electrolyzer creates hydrogen gas. Nel offers two types of electrolysers, alkaline and PEM (proton exchange membrane). We’ve been making alkaline electrolysers for 90 years in Norway and PEM electrolysers for 23 years in the U.S. In Norway, Nel is dramatically increasing its production capacity. Currently, it’s at 40 megawatts per year (input electrical power to electrolysis) and will increase shortly to 500 megawatts per year with the completion of a new plant, and then to 2,000 megawatts per year with subsequent expansions. In the U.S., the company is increasing its production for PEM systems to 50 megawatts per year, with additional expansion planned as demand increases. Alkaline electrolysis is admittedly a more mature technology with most of the technological innovations already absorbed. Although some technological innovation may still contribute, the cost reductions available for alkaline electrolysis are primarily around volume purchasing and equipment simplification. By comparison, PEM technology is a newer technology with room for significant technological innovation.

In the hydrogen fueling segment, we’re also the leading manufacturer of hydrogen fueling stations, with over 110 H2Station™ systems in 13 countries. We have been manufacturing our renowned compact hydrogen fueling stations at our Denmark facility for 16 years at a capacity of 300 per year.

Hydrogen Growth

Nel is bullish on the opportunities for hydrogen electrolysis within the hydrogen market. For instance, right now, only 1% of hydrogen is generated with electrolysis and that is forecasted to grow to greater than $20 billion/year within the existing market alone. The overall hydrogen market is set to grow by 8 times, and the electrolyser market potential is forecasted to grow more than 800 times over the next 20 to 30 years. All of this is driven by the regulations to lower surplus demand for fuel; decreased crude quality which requires more hydrogen for processing; electrification of the transport sector; and the move from coal to hydrogen in various industries. The steadily-growing industrial applications are many such as the food, glass, chemical, laboratories, thermal processing, steel, and power industries. Newer markets experimenting with hydrogen now include, ammonia, refineries, methanol/synthetic fuels, cement, remote power, gas pipelines, energy export and believe it or not, fish farming!

We have been manufacturing our renowned compact hydrogen fueling stations at our Denmark facility for 16 years at a capacity of 300 per year.

There are vast opportunities in power generation alone, and many readers may be familiar with HYBRIT, a northern European hydrogen steel plant in its pilot stage now. Transportation and mobility are another fast-growing market both for hydrogen production and fueling. Hydrogen is now accepted as a relevant form of fuel for all methods of transport.

Reaching Cost Parity

There is encouraging news on the cost front also. With falling LCOE (levelized cost of energy) of wind and solar prices, renewable hydrogen follows the same path, as electrical power constitutes 70 to 80% of hydrogen’s total cost. These prices are expected to drop even further with solar down 71% and onshore wind 58%. Renewable hydrogen becomes competitive with fossil fuels in most markets at $30/MWh. Nel is establishing a new manufacturing plant targeting more than 40% cost reduction and even further CAPEX (capital expenditure) reduction is expected with the increased volume we are anticipating. In fact, we project the CAPEX will drop below steam methane reforming over time. Electrolysis is expected to be the preferred production method if the OPEX (operating expense) is low enough or at parity with alternative production methods. Nel’s green hydrogen cost target is 1.5 $/kg by 2025.

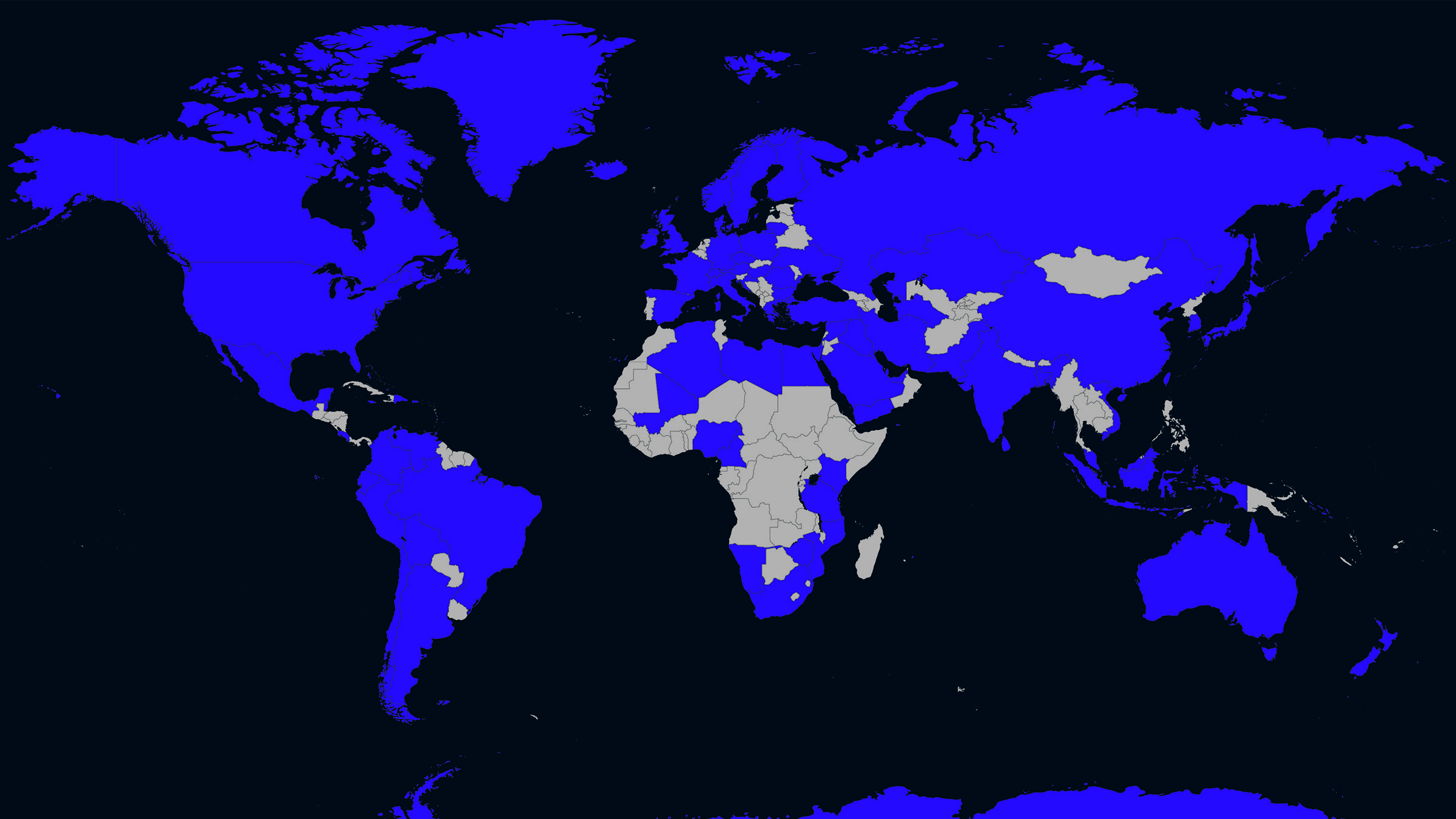

Nel World Installation Map_L4C

With more than 3,500 reliable, cost efficient electrolysers installed around the globe, Nel is the recognized industry leader of Alkaline and PEM water electrolysis. Source: Nel

Meeting Global Demand

To maintain Nel’s leadership position in the hydrogen market and keep reducing costs, we have embraced and nurtured a world-class culture of continuous improvement. We are preparing for the increased hydrogen demand on a global scale. One example is our capacity expansion at our electrode manufacturing facility in Herøya, Norway. Coming online soon are fully automated production lines applying the latest Industry 4.0 techniques in staging, equipment, assemblies, software, and factory connectivity. There are fewer process steps to reduce our factory footprint and energy and chemical consumption. The more efficient processes have led to better product performance for our customers. We have tripled our staff, concentrated on core competencies, and expanded our applications knowledge base. Further, we are vastly increasing the size and capacity of our electrolyser cell stacks by a factor of 20, boosting the energy capability of a single stack to generate hydrogen reliably and efficiently. The company is also reducing the CAPEX of its PEM electrolysis equipment by transitioning from largely handmade membrane electrode assemblies containing platinum group metals to volume production roll to roll manufacturing of membrane electrode assemblies.

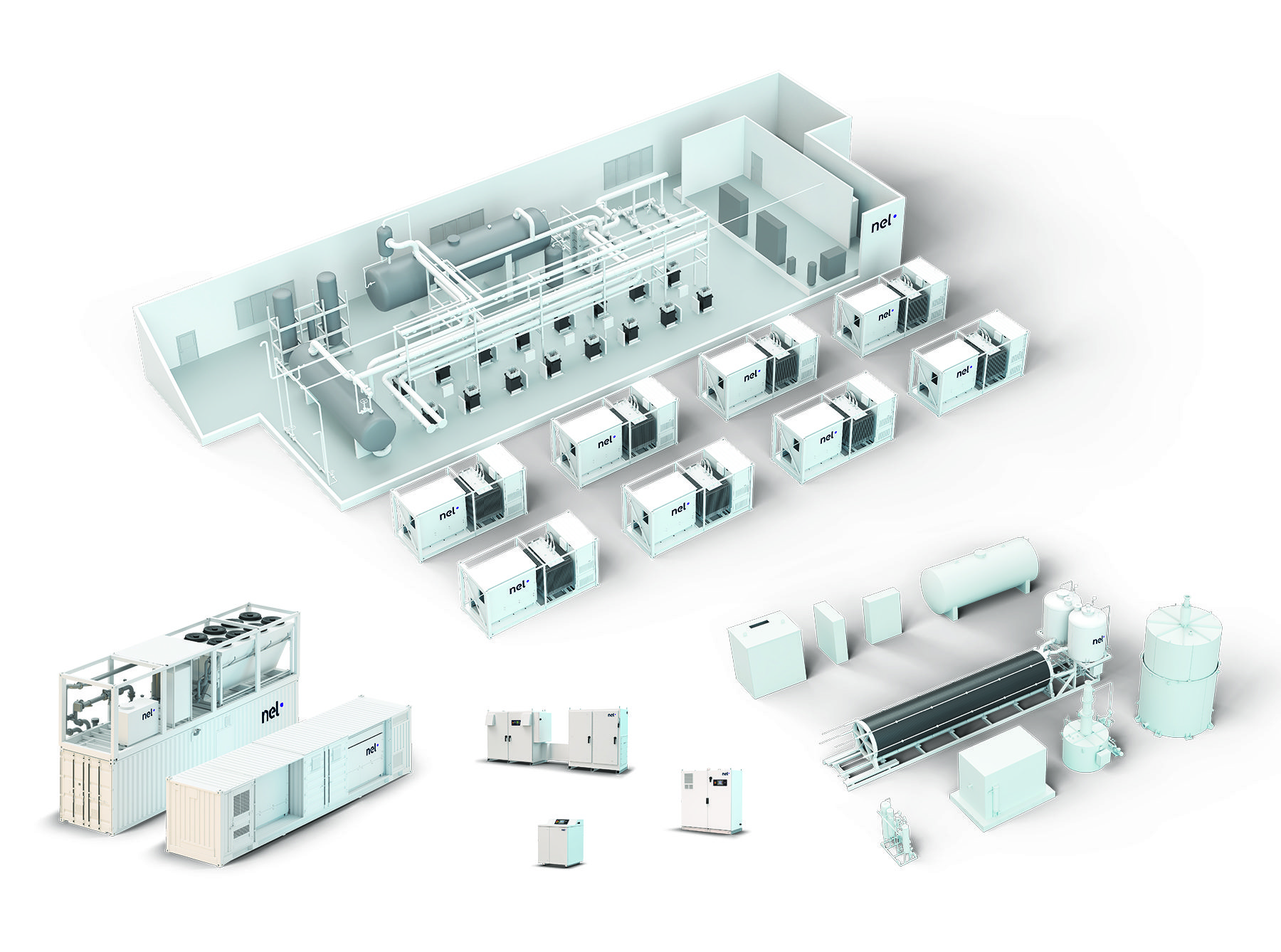

NelElectrolysers-CMYK

Nel offers a full range of Alkaline and PEM electrolysers to cover the hydrogen output requirements of any application. Source: Nel

Hydrogen fueling station sales are expected to grow greater than 30% each year between now and 2030. Hydrogen is becoming increasingly relevant in all forms of mobility including forklifts, busses, delivery trucks, long-haul trucks, construction equipment, passenger cars and trucks, trains, fast ferries, and car ferries. The challenge is to get to a cost parity with diesel fuel prices, which would be less than $5/kg. We at Nel anticipate this will happen soon, by 2025. Nel is also addressing other key challenges such as fast fueling dispensing and the space required to accommodate the new hydrogen infrastructure products including supply cabinets, supply and fueling storage tanks, station modules, and dispenser stations. Nel is in the unique position to ramp up its capacity to meet the demand with our already proven in-house developed technologies, our full value-chain services, our operations and maintenance organization in key markets, our standardized and certified products, along with our known world’s largest manufacturing capacity in this very specialized market. The goal: evolve to 10x capacity and decrease CAPEX by 90% by 2030.

In sum, Nel Hydrogen is well-positioned for the growing hydrogen market. We possess the deep technology knowledge stemming from our almost 100-year history in hydrogen production technologies. This fundamental knowledge-base serves as the springboard for our leadership position for current and future developmental platforms. The company is scaling-up capacity with expertise and robust development to meet the projected demand for hydrogen solutions in the coming decade to take full advantage of these opportunities.